YN-A500 Polymer (EVA/HDPE) Composite Self-Adhesive Waterproof Membrane

Product Overview

YN-A500 Polymer Composite Self-Adhesive Waterproof Membrane is a type of self-adhesive waterproof membrane composed of a layer of silicone creep rubber asphalt self-adhesive glue and a polymer composite sheet. The polymer sheet includes high-performance materials such as HDPE, EVA, and ECB composite sheets. This material can be laid wet and can adopt the pre-laid inverted adhesion method. Different construction methods can be flexibly adopted according to different design requirements.

Product Features

- Excellent elongation and tear resistance.

- Resistance to chemical corrosion from various acids and alkalis.

- Strong physicochemical indicators with a service life of over 50 years.

- Excellent adhesive sealing performance.

Specification and Model

Thickness: 1.2mm/1.5mm/2.0mm

Width: 1.0m/1.5m/2.0m/3.0m

Length: 25m/20m/15m

Scope of Application

It is applicable to high-level and critical waterproofing projects such as green roofs, grain storage facilities, air-raid shelters, sewage treatment plants, artificial lakes, basements, tunnels, subways, high-speed railways, bridges, and landfill site seepage prevention.

Precautions

- Before bonding the seams of the membrane, avoid contamination of the overlapping surfaces with water, cement mortar, or dust to ensure proper seam adhesion.

- After completion, protect the waterproofing layer well and avoid damaging the membrane with metal or hard objects.

- After seam construction, inspect the seams of the membrane and seal any damage found with sealing material.

- The construction process should be carried out step by step without crossing over different stages.

- Avoid contact with organic solvents and keep away from fire sources.

- Store the membrane in a dry and well-ventilated environment to prevent exposure to sunlight and rain.

Construction Process

-

Pre-laid Inverted Adhesion Method

Clean the base surface → Treat local nodes → Pre-lay the waterproof membrane → Overlap edges, terminate, and seal → Remove the release paper on the membrane surface → Pour concrete -

Wet Laying Method

Clean the base surface → Prepare cement mortar → Treat nodes → Lay the waterproof membrane → Overlap and terminate → Seal → Carry out maintenance

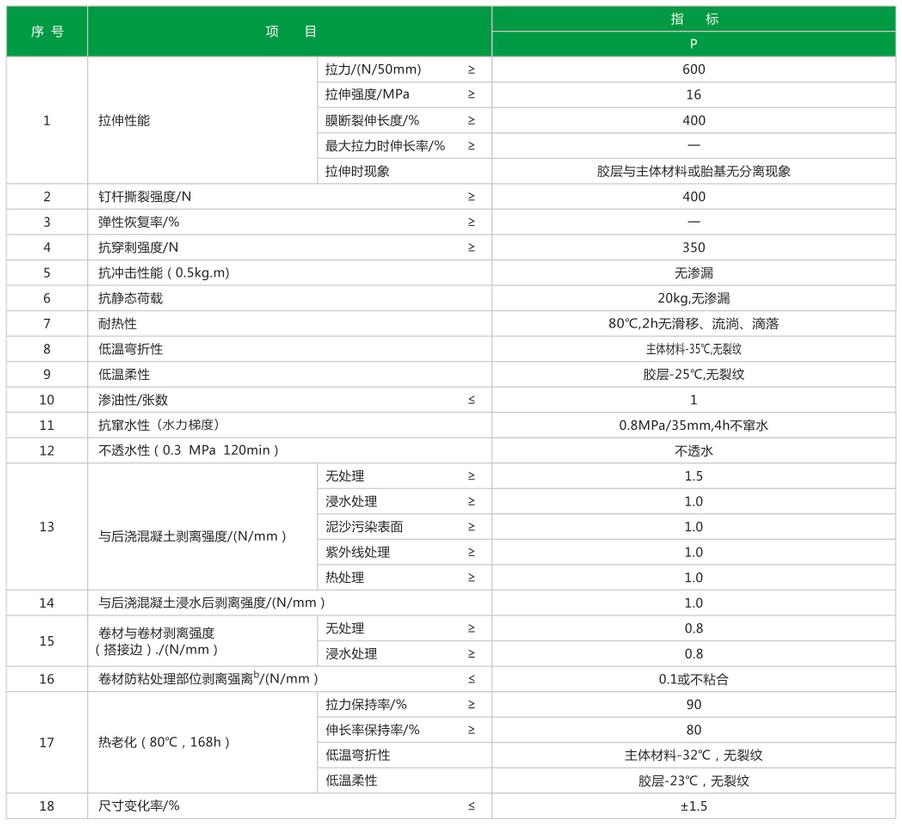

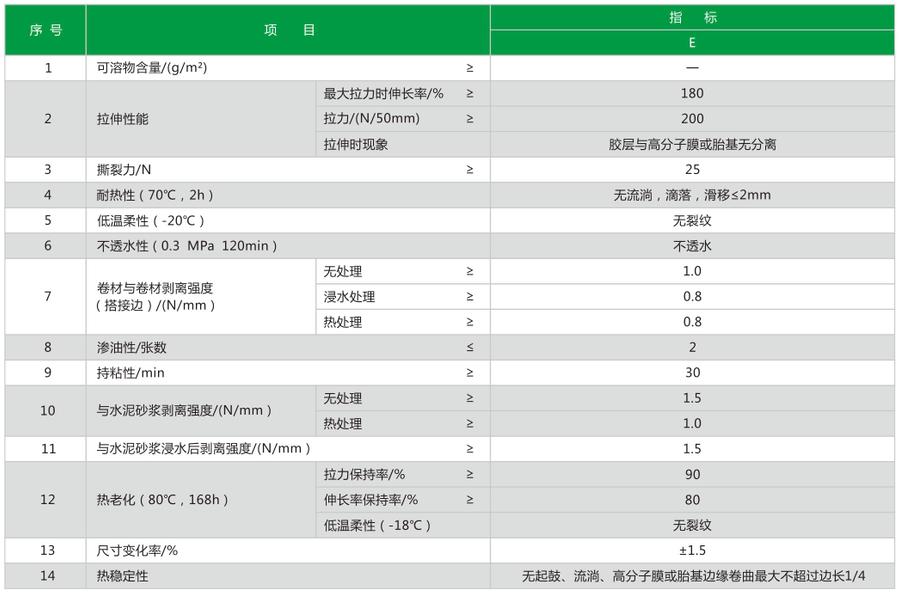

Technical Specifications

Execution Standard: GB/T 35467-2017 (Wet Laying, Category E)

Execution Standard: GB/T 23457-2017 (Pre-laid, Category P)