YN-A760 High-Strength Cross-Linked Membrane Polymer Composite Self-Adhesive Waterproof Membrane

Product Introduction

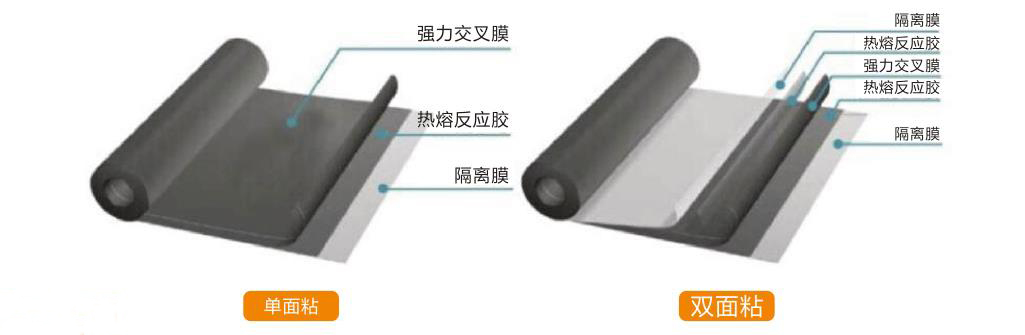

YN-A760 High-Strength Cross-Linked Membrane Polymer Composite Self-Adhesive Waterproof Membrane is a self-adhesive polymer-based waterproof membrane made with a high-strength cross-linked membrane as the surface reinforcement material, coated with rubber-modified asphalt self-adhesive glue containing active additives.

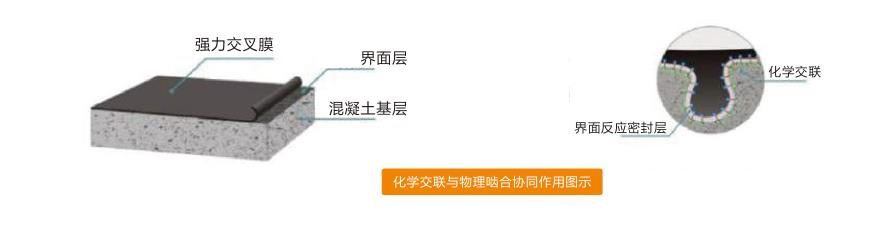

During installation, this membrane utilizes the wet laying method to achieve crosslinking and engagement between the pressure-sensitive reactive adhesive of the membrane and the cement gel. The high-strength cross-linked membrane employed offers excellent physical properties, particularly in terms of high tear strength and dimensional stability, forming a fully adhered, water-tight, and stable waterproof layer.

Product Features

-

Physical Properties: The high-strength cross-linked membrane employs cross-lamination technology, providing high tensile strength, elongation, tear resistance, and impact resistance.

-

Bonding Performance: The membrane undergoes chemical reactions and physical adsorption with polymer cement and the concrete structural layer, forming a physicochemical bonding layer between the membrane and the structural layer that is much stronger than physical adsorption bonding.

-

Waterproofing Effect: It possesses strong "waterproofing" capabilities, non-diffusion, and excellent self-healing abilities.

-

Simplified Construction Process: It interacts with polymer cement to form a tightly bonded layer. It has low requirements for the base layer, can shorten the construction period, save construction costs, and is easy to lap.

Precautions

- The base layer should be flat, clean, and free of ponding water.

- Detailed node treatments should be carried out for areas such as pipes, internal and external corners, flat surfaces, and expansion joints.

- Walking on the surface is strictly prohibited before the polymer cement mortar dries, and subsequent construction can only proceed after the polymer cement mortar has completely hardened.

Transportation and Storage

- It should be packaged in dedicated plastic bags with airtight sealing and stored in a dry, well-ventilated environment to prevent exposure to sunlight and rain.

- Different categories and specifications should be stacked separately without tilting or cross-stacking.

- The waterproof membrane should be laid horizontally, and the stacking height should not exceed five layers.

- During transportation and storage, it should be kept away from fire sources. The storage temperature should not exceed 35°C, and the storage period is one year from the date of production.

Construction Process

Base layer preparation → Node treatment → Positioning and snapping lines → Preliminary laying of waterproof membrane → Application of cement mortar → Laying of waterproof membrane → Rolling and venting → Lap joint and termination treatment of waterproof membrane → Acceptance

Specification and Model

Width: 1.0m;

Thickness: 1.5mm, 2.0mm;

Length: 25m, 20m, 15m;

Note: Other specifications and sizes can be determined through negotiation between the supplier and the buyer.

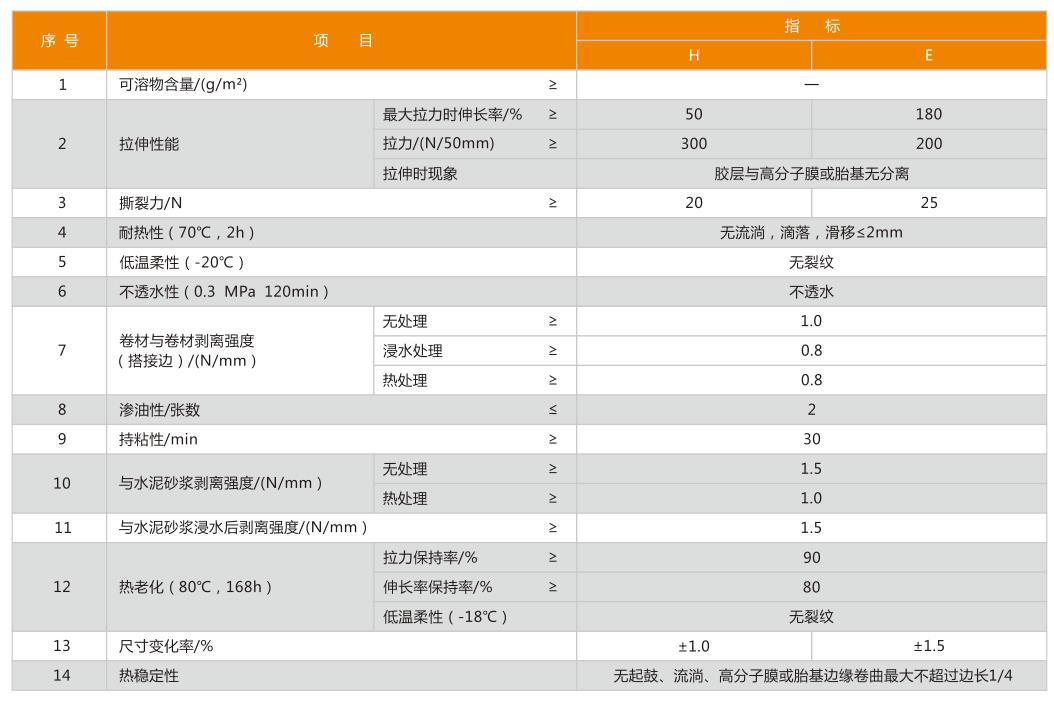

Technical Specifications

Execution Standard: GB/T 35467-2017 (Category H, Category E)