YN-B705 GTS New Plastic-Fiber Polymer Self-Adhesive Waterproof Membrane

Product Overview

YN-B705 GTS New Plastic-Fiber Polymer Self-Adhesive Waterproof Membrane is a high-molecular membrane-based waterproof material made by using long-fiber geotextile as the surface reinforcing material and covered with rubber-modified asphalt self-adhesive glue containing active additives. This membrane can be bonded using cement paste (wet laying method) or through self-adhesive bonding (dry laying method) during construction. It exhibits certain resistance to heavy pressure, scratching, and puncturing, making it suitable for waterproofing projects with crossing construction processes, limited working spaces, and high construction efficiency.

Product Features

- Enhanced Surface Reinforcement: Utilizes long-fiber geotextile for superior reinforcement and durability.

- Dual Adhesion Methods: Can be installed using either cement paste (wet laying) or self-adhesive bonding (dry laying), providing flexibility in construction.

- Excellent Pressure, Scratch, and Puncture Resistance: Designed to withstand heavy loads, scratches, and punctures, ensuring long-term performance.

- Suitable for Complex Conditions: Ideal for waterproofing projects with challenging conditions, such as crossing construction processes, limited workspaces, and tight schedules.

- Self-Adhesive and Easy to Apply: Simplifies installation process, reducing labor costs and improving efficiency.

- Broad Application Scope: Suitable for various waterproofing needs in industrial and civil buildings, underground structures, subway tunnels, ponds, canals, bridges, highways, and more.

Precautions

- For geotextile-covered membranes, the butt joint method should be used for horizontal lap joints.

- Seal the membrane with polymer cement mortar or bond it with double-sided self-adhesive strips. The width of the double-sided self-adhesive strips used for butt jointing should not be less than 150mm.

- When dry laying, the base surface must be dry, flat, and clean.

- When wet laying, prepare cement paste using polyethylene powder and cement of grade 325 or higher, and stir evenly until it forms a paste.

Scope of Application

Waterproofing projects for basements, roofs, ponds, and other similar structures.

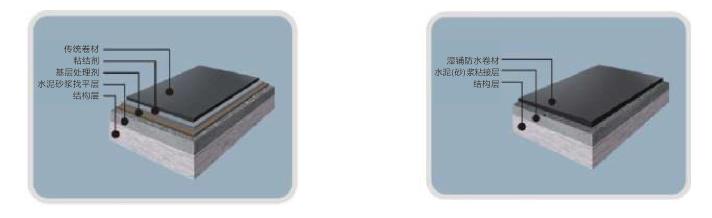

Construction Process

- Dry Laying Method

- Clean the base surface

- Apply base treatment agent

- Treat nodes and corners

- Lay the waterproof membrane

- Overlap and receive seams

- Seal the seams

- Wet Laying Method

- Clean the base surface

- Prepare cement mortar

- Treat nodes and corners

- Lay the waterproof membrane

- Overlap and receive seams

- Seal the seams

Specification and Model

Width: 1m;

Thickness: 1.5mm, 2.0mm;

Length: 20m, 15m;

Note: Other specifications and sizes can be determined through negotiation between the supplier and the buyer.

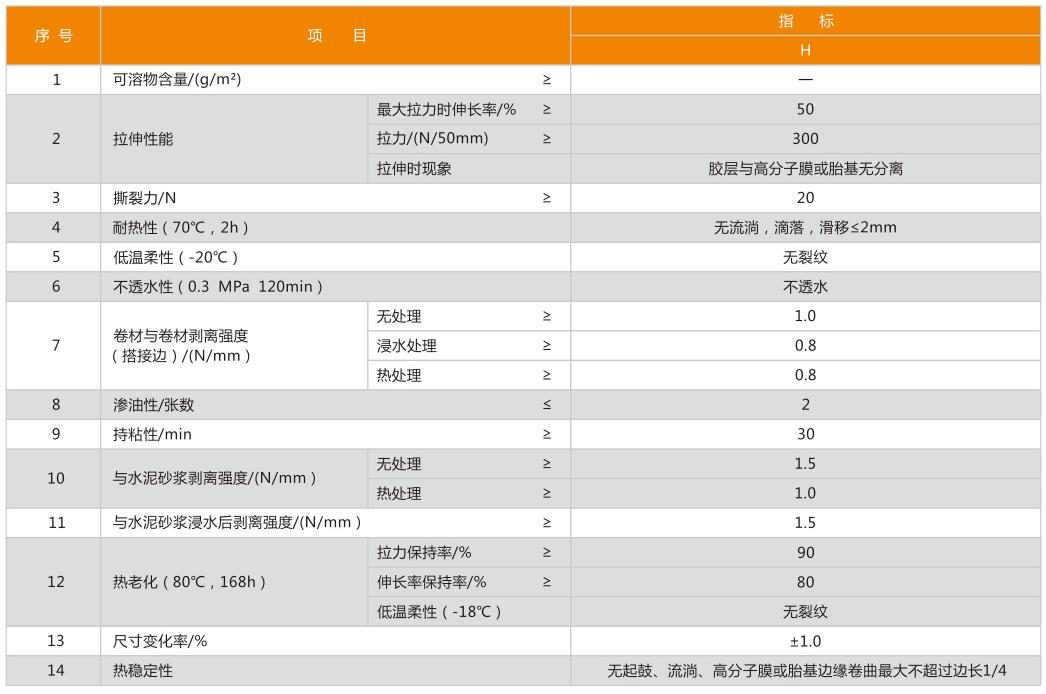

Technical Specifications

Execution Standard: GB/T 35467-2017 (Category H)