YN-C802 Single-Component Polyurethane (Synthetic Polymer) Waterproof Coating

Product Overview

YN-C802 Single-Component Polyurethane (Synthetic Polymer) Waterproof Coating is a flexible polymer coating formulated through a polymer synthesis reaction process using advanced foreign technology, imported raw materials, and additives. It forms a single-component reactive wet-curing rubber film. This material boasts advanced technology, excellent product performance, and ease of use, facilitating convenient construction for customers.

Product Features

- As a single-component synthetic polymer waterproof coating, it forms an ultra-elastic rubber membrane with PU resin and other chemical raw materials.

- It features high strength, high elongation, high elasticity, fatigue resistance, aging resistance, etc.

- Ready-to-use upon opening the bucket, it has lenient requirements on the moisture content of the base layer and can be applied on relatively wet surfaces, making it easy to operate and convenient for construction.

- It has excellent weather resistance and can adapt to climate changes in hot and cold regions.

- It undergoes a chemical reaction with moisture in the air (H2O) to form a tough, flexible, and seamless rubber membrane.

- The color is adjustable, meeting the personalized requirements of different customers for surface colors.

Construction Process

Base layer preparation → Detailed treatment → First coat application → Second coat application → Third coat application → Construction inspection and acceptance

Scope of Application

It is suitable for waterproofing roofs and underground works of civil and industrial buildings, as well as municipal, bridge, subway, dam, and other engineering projects. It can also be used for waterproofing kitchens, bathrooms, balconies, parking lots, and other projects. It is especially suitable for waterproofing works in areas with complex shapes.

Key Points of Construction

- The base surface should be clean, solid, and free of visible water. Any cracks or defects should be repaired and sealed first. Pipe fittings, sanitary facilities, and floor drains connected to the base layer must be securely fastened and not loose.

- Use a rubber scraper to evenly apply the coating on the base surface, ensuring that the coating thickness meets the design requirements. There should be no missed brushing, bubbling, or layer separation.

- The time interval between each coating application should be based on when the film is no longer tacky to the touch. Generally, 2-3 coats are required.

- For corrosion protection of metal plates and pipes, rust removal should be performed first, followed by coating application.

- During construction, it is generally required to apply the coating in three coats. After the first coat has solidified, apply the second coat, with the brushing direction perpendicular to the first coat. To increase the adhesion between the waterproof coating and the rigid protective layer, clean sand grains can be sparsely sprinkled on the surface of the wet coating to increase its roughness.

Precautions

- The construction temperature should be between 5℃ and 35℃. Construction is not allowed in rainy or snowy conditions.

- Construction should be carried out in well-ventilated areas, and construction personnel should take appropriate safety precautions.

- The coating should be used up in one go after opening.

- Before the coating film dries and solidifies, walking on the waterproof layer and stacking hard or sharp objects are strictly prohibited to prevent damage to the waterproof layer.

- Please read the "Product Safety Instructions" before construction and follow the guidance provided by Yuneng Waterproof for construction operations.

Packaging, Transportation, and Storage

- Store in clean, dry, and airtight iron drums.

- During transportation and storage, avoid exposure to sunlight and rain, keep away from fire sources, prevent collisions, ensure ventilation, and maintain a storage temperature between 5℃ and 25℃, preferably not exceeding 40℃.

- The height should not exceed three layers during transportation, storage, and stacking.

- Under normal transportation and storage conditions, the shelf life is 6 months.

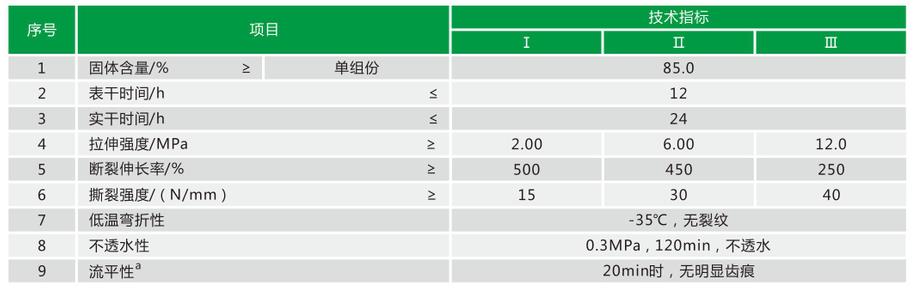

Technical Specifications

Execution Standard: GB/T 19250-2013 (Category S)