YN-C907 Lidun Non-curing Rubber Asphalt Waterproof Coating

Product Overview

YN-C907 Lidun Non-curing Rubber Asphalt Waterproof Coating is a high-solid content hot-melt asphalt waterproof coating. It remains uncured after long-term exposure to air and maintains its viscous gelatinous property; it has strong self-healing ability, adheres instantly upon contact, and is difficult to peel off, maintaining excellent adhesive performance even at -25°C. It addresses issues such as cracking, fatigue damage, or premature aging of the waterproof layer due to stress transfer from cracks in the substrate to the waterproof layer when under high stress. Additionally, the viscous nature of the creep material allows it to effectively seal capillary pores and cracks in the substrate, solving the problem of water leakage through the waterproof layer. Furthermore, it resolves the issue of poor compatibility when used in combination with waterproof membranes and waterproof coatings.

Multiple construction methods, such as hot scraping and hot grouting, can be employed for its application.

Product Features

- Creep Performance: It effectively absorbs stress from the substrate. When external stress is applied, it immediately undergoes deformation, protecting the waterproof layer from damage, enhancing its reliability, and extending its lifespan.

- Application Performance: It forms a film instantly, requiring no curing, and allows immediate progression to the next construction step. With good affinity, it can bond with any material to form a stable waterproof coating. It has low requirements for substrate flatness and does not require the application of a primer.

- Adhesive Performance: It adheres upon contact and is difficult to peel off, capable of filling deformation cracks in the substrate.

- Temperature Adaptability: It can withstand high temperatures of 60~70°C and remains flexible at -25°C.

- Self-Healing Property: When the waterproof layer is damaged by external forces, the damage point will not expand, and there will be no water leakage at the bottom of the waterproof layer. Due to the creep action of the coating, the damage point can gradually be repaired, significantly improving the reliability of the waterproof layer.

- Environmental Performance: It contains no organic solvents and has a solid content of over 99%. The construction process is smoke-free and odorless.

- Elongation Performance: With an elongation rate of over 1000% and an extensibility of over 60mm, it prevents damage to the waterproof layer due to substrate misalignment, ensuring that the building structure remains intact and sealed.

- Chemical Resistance and Aging Resistance: After immersion tests in acid, alkaline, and salt media, as well as thermal aging treatment, its performance remains above 90%.

Scope of Application

It is widely used in roofing and underground waterproofing projects for industrial and civil buildings; as well as grouting and leakage stopping projects for deformation joints.

Key Construction Points

- Substrate Preparation: The substrate should be smooth, solid, and free of visible water. It is advisable to clean off any floating dust on the substrate before construction.

- Detail Treatment: Internal and external corners, as well as corners where planes meet elevations, should be rounded off with a radius preferably between 40 and 50mm.

- Scraping Application: Using professional equipment, evenly scrape the molten coating to the required thickness with a scraper, ensuring complete coverage without missing any areas. If a waterproof membrane is to be used in conjunction, the membrane laying should be completed as soon as possible to ensure construction quality. The lap seams should also be bonded with hot-melt coating. During spray application, the spray pressure and the reciprocating frequency of the spray gun should be kept constant to effectively control the coating thickness.

- Membrane Laying: Lay the waterproof membrane on the surface of the already applied non-curing rubberized asphalt waterproof coating, ensuring it is straight, flat, and wrinkle-free. The overlap width of the membrane should be 70-100mm, and the overlap area should be cold-adhered by scraping non-curing rubberized asphalt waterproof coating within the overlap width. After overlapping the membranes, use a roller to press them down.

- Protective Layer Construction: Once the quality inspection is passed, the protective layer can be constructed according to the design requirements, with corresponding concrete or cement mortar protective layers.

Transportation and Storage

- During transportation, prevent exposure to rain, sunlight, pressure, and collision to keep the packaging intact.

- The product should be stored in a well-ventilated, dry, and shaded area to prevent direct sunlight. The storage temperature should not exceed 40°C.

- Under normal storage and transportation conditions, the shelf life is 6 months.

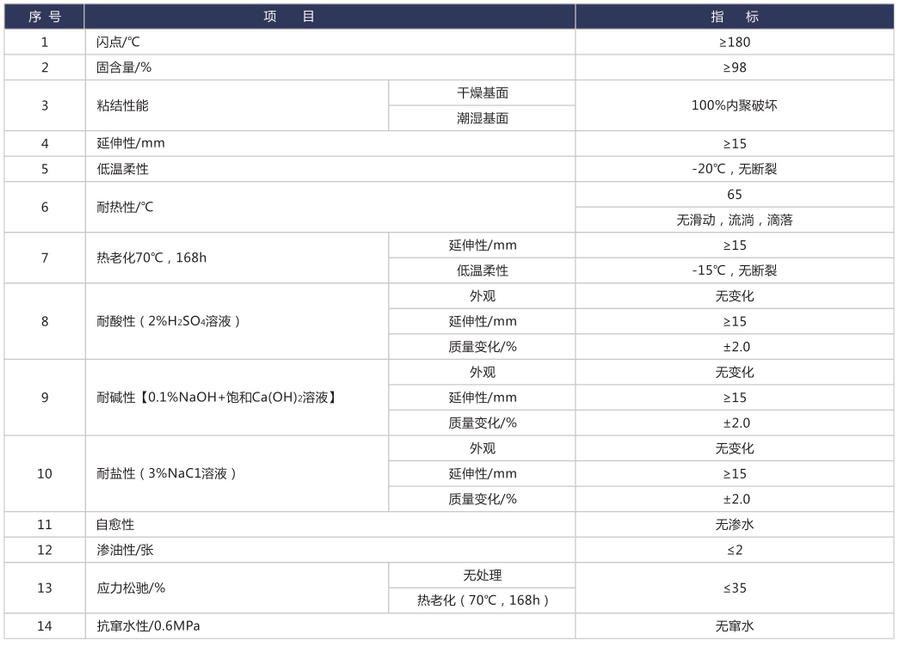

Technical Specifications

Execution Standard: JC/T 2428-2017