YN-T709 Copper-Based SBS Modified Asphalt Waterproof Membrane with Root Puncture Resistance

Product Overview

YN-T709 Copper-Based SBS Modified Asphalt Waterproof Membrane with Root Puncture Resistance is an asphalt-based waterproof membrane specifically designed to resist root puncture. It utilizes a special composite copper base as its reinforcing layer, coated with SBS modified asphalt that has been fortified with a root barrier agent. Both sides of the membrane are covered with polyethylene film (PE) as the isolating material.

Product Features

- It possesses dual functions of waterproofing and preventing plant root penetration.

- It prevents root puncture while not affecting the normal growth of plants.

- It exhibits excellent elongation and high tear resistance, accommodating creep in the structural layer.

- It can form a high-strength waterproof layer with strong resistance to pressure water.

- It demonstrates high and low temperature resistance, suitable for both hot and cold regions.

- An additional self-adhesive layer can be applied to enhance ease of installation during construction.

Key Structural Points of the Planting System

The planting system generally consists of multiple layers, including the vegetation layer, planting soil, filter and water storage layer, drainage layer, protective layer, polymer-modified asphalt waterproof layer with root puncture resistance, ordinary SBS modified asphalt waterproof layer, leveling layer, insulation layer, grading layer, structural slab, and other components.

Scope of Application

It is suitable for waterproofing areas in basements, roofs, and tops of various buildings, as well as other waterproofing zones that require waterproofing function and resistance to plant root penetration.

Construction Method

I. Construction Tools:

Generally, the following tools should be available: gasoline torch or hot-melt spray gun, dust blower, broom, mixing bucket, roller brush or palm brush, scraper, scissors, steel tape measure, etc.

II. Requirements for the Base Layer:

-

Before laying the waterproof membrane, the base layer must be strictly inspected. The base surface must be solid and flat, with no bulges, concave-convex areas, or sanding.

-

The base layer should be dry, with a moisture content of less than 9% before construction can begin.

-

Before construction, the protruding cement mortar residue, dust, and debris on the base layer should be carefully removed and cleaned.

-

For complex areas, the internal and external corners should be curved. Additional layers should be added to special areas such as the root of pipes and drainage outlets.

III. Laying and Bonding of the Waterproof Membrane:

-

Position the waterproof membrane correctly and then bond it using either the cold adhesion method or the hot-melt method. The hot-melt method provides better bonding results, which can reduce costs and prevent future hollow drumming in the waterproof interlayer.

-

Reserve a 10cm-wide seam overlap. Light the torch and evenly heat the membrane. Once the membrane surface melts, immediately lay it forward. During rolling, be careful not to roll in air or foreign objects. The membrane must be compressed, flattened, and aired out. Before the membrane cools, use a trowel to seal the edges. Then, seal the edges and complex areas to prevent curling.

Specification and Model

Thickness: 4.0mm

Length: 7.5m

Technical Specifications

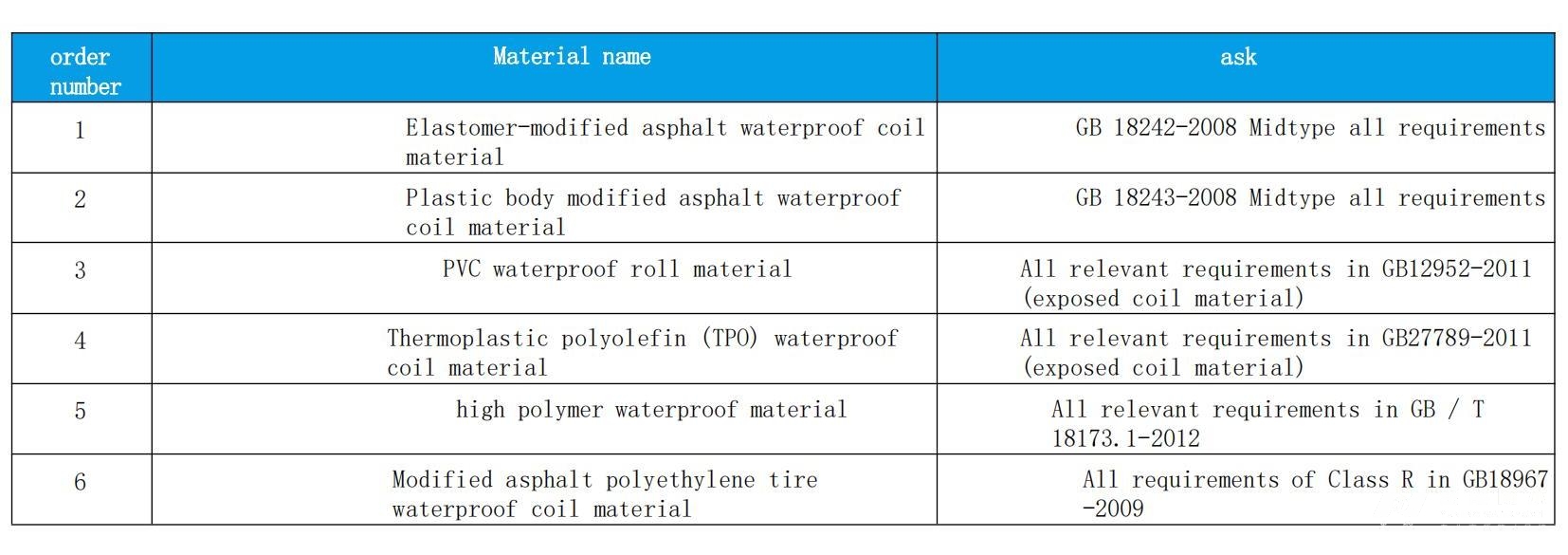

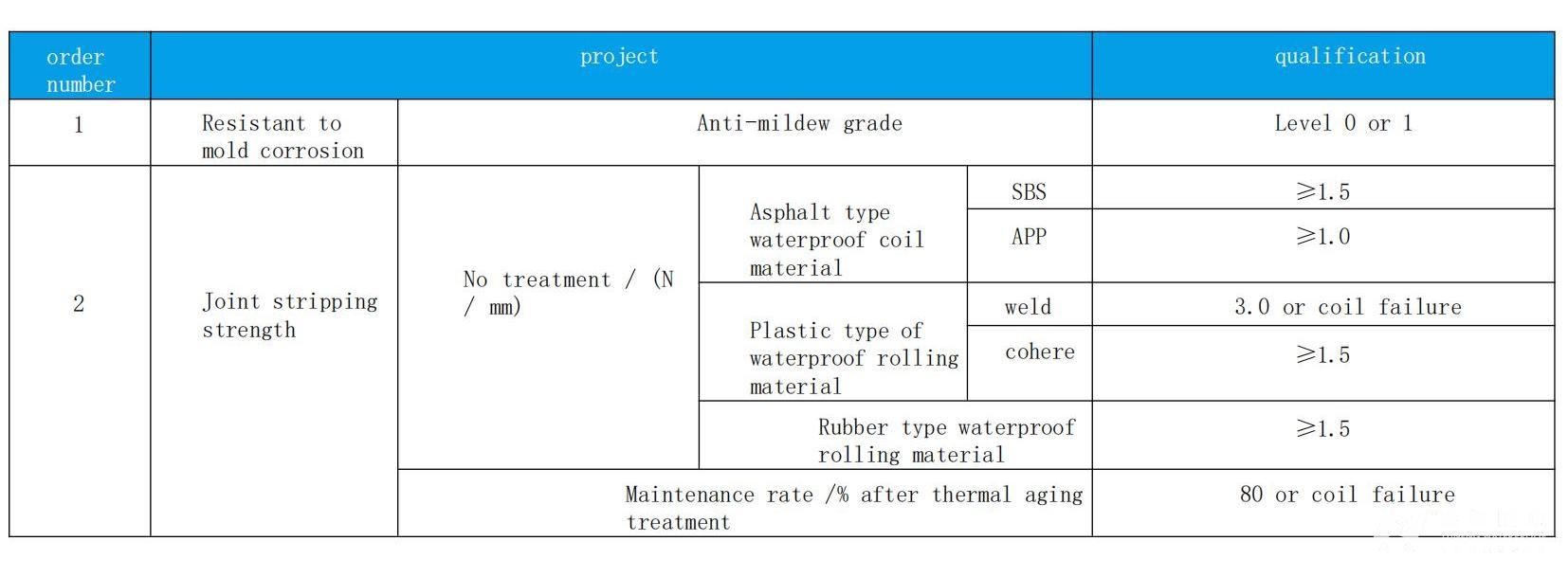

The product performance includes basic performance and application performance.

Execution Standard: GB/T 35468-2017

Basic Properties and Related Requirements of Waterproof Membrane with Root Puncture Resistance